What is UPVC plastic formwork?Why using UPVC to manufacture PVC formwork?

Definition of UPVC

UPVC, the full name is Unplasticized Polyvinyl Chloride, is also named Plastic Steel, or PVC-U. It is the upgrading of general PVC that removes plasticizers to achieve better engineering properties, so as to retain the rigid chain structure, and increase the strength.

It strictly adheres to the "Three-No-addition" principle: no plasticizers, no heavy metal stabilizers, no calcium carbonate fillers.

Environmental friendly, corrosion resistant, formaldehyde-free, has excellent UV resistance performance and outdoor ageing resistance, UPVC is widely applied to windows /doors frames, construction, food-grade piping, and industrial sewage pipe, etc.

Except UPVC, there are other different plastic formwork materials including general PVC, PP, ABS in the markets.

Since 10+ years ago, UPVC has been proved to be the most qualified and the optimal raw material selection for PVC formwork.

This is a well-known point in this industry by almost manufacturers.

JINGFANG® UPVC plastic formwork adopts “New & Pure UPVC” as the solo main raw material, which accounts for more than 95% (the rest 4~5% is for necessary additives).

Comparison between UPVC and general PVC:

Advantages of UPVC:

1. Higher strength.

2. Better UV resistance and temperature resistance.

3. Environmental, no plasticizers, no heavy metal stabilizers, formaldehyde-free.

4. Higher resin purity.

5. Over 4 times better outdoor anti-aging performance than general PVC.

Disadvantages of UPVC:

Higher cost.

But, attention to distinguish: white PVC resin and white UPVC are two different raw materials.

PVC resin is the main raw material for WPC/PVC foam boards which are applied in ad., decoration or furniture, but it’s not good for PVC formworks because of its less strengh.

“New & Pure UPVC" is the optimal raw material for PVC formwork. But to mislead customers and save costs, some unresponsible suppliers deny this widely recognized general knowledge.

They use PVC resin+overmuch calcium powder+recycled PVC/PP/ABS materials which offer much lower costs but poor performance, such as the new knock offs mentioned in the previous pages.

When a supplier denies this point or misleads you, it implies that he doesn't want to use or have never utilized the qualified UPVC to manufacture PVC formworks.

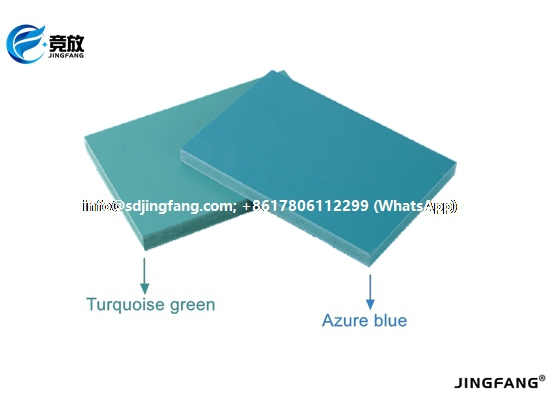

Therefore, do not judge raw materials from colors only.

Shandong Jingfang Import and Export Co., Ltd. is specialized in developing, manufacturing and sales of JINGFANG® UPVC plastic formwork.

· New & pure UPVC as the solo main raw material

· 10+ years manufacturing and export experience

· Strict QC every 1-2 hours during manufacturing

· One of the earliest manufacturers, the only single-minded manufacturer

Our main raw material “New & Pure UPVC” accounts for over 95%, and we never use any recycled PVC/PP/ABS materials, can guarantee qualified strength, elasticity modulus and UV-resistance, thoroughly solve the deformation/cracking/bending problems of unqualified products.

Our corporate culture is "Quality competing, sincerity blooming",which means “Jing Fang”in Chinese, means our factory is based on integrity and quality. On the basis of sincerity, we constantly strive for higher and higher quality. So that our company name is “Shandong Jingfang”.

With advanced automatic production lines, professional production team and independent international trading team, we promise you the best product & import service and are 100% confident being one of the most professional Chinese factory manufacturing this product.