PVC plastic formwork, Construction 50+ times Reuse, Advantages and Application Cases

Definition & Brief Introduction of PVC Plastic Formwork:

PVC plastic formwork was created by over 10 years ago under the worldwide hot trend of "replacing wood with plastic" as a new type of plastic formwork that can substitute plywood/wood formworks, so as to save the forest sources. Recent 3 years, it is being well-known by more and more countries.

Compared with traditional wood/plywood formwork materials, the most important advantage of PVC plastic formwork is that it can be reused for at least 50 times in plain wooden structures, and much more times in metal frames which offer good protection to formwork sheets.

Similar to plywood formworks, the popular sizes of PVC plastic formwork are also 4'x8'x12/15/18mm, as well as the similar applications including wall formwork, slab formwork, column formwork, stair formwork, etc.

Specifications & Essential Information of PVC plastic formwork:

| Trademark/Brand: | JINGFANG® PVC plastic formwork |

| Raw material: | UPVC, also named Plastic-steel PVC, accounts for over 95% |

| Applications | Wall, column, slab/floor, stairs, high-speed way, bridge, tunnels, etc. |

| Reuse times | At least 50 times in different structures |

| Width: | Up to 1300mm available |

| Length: | No limits, can be customized |

| Thickness: | 6~21mm available |

| Density: | 700kg/m³±1% (standard), and the 600~900kg/m³ can be customized |

| Color: | Turquoise Green/Azure blue (original), others can be customized |

| Loading & packing: | In bulk, or with pallets |

| FOB port: | Qingdao, Lianyungang, Tianjin, Shanghai, etc. |

| Export transportation method: | FCL/LCL by sea, road or railway |

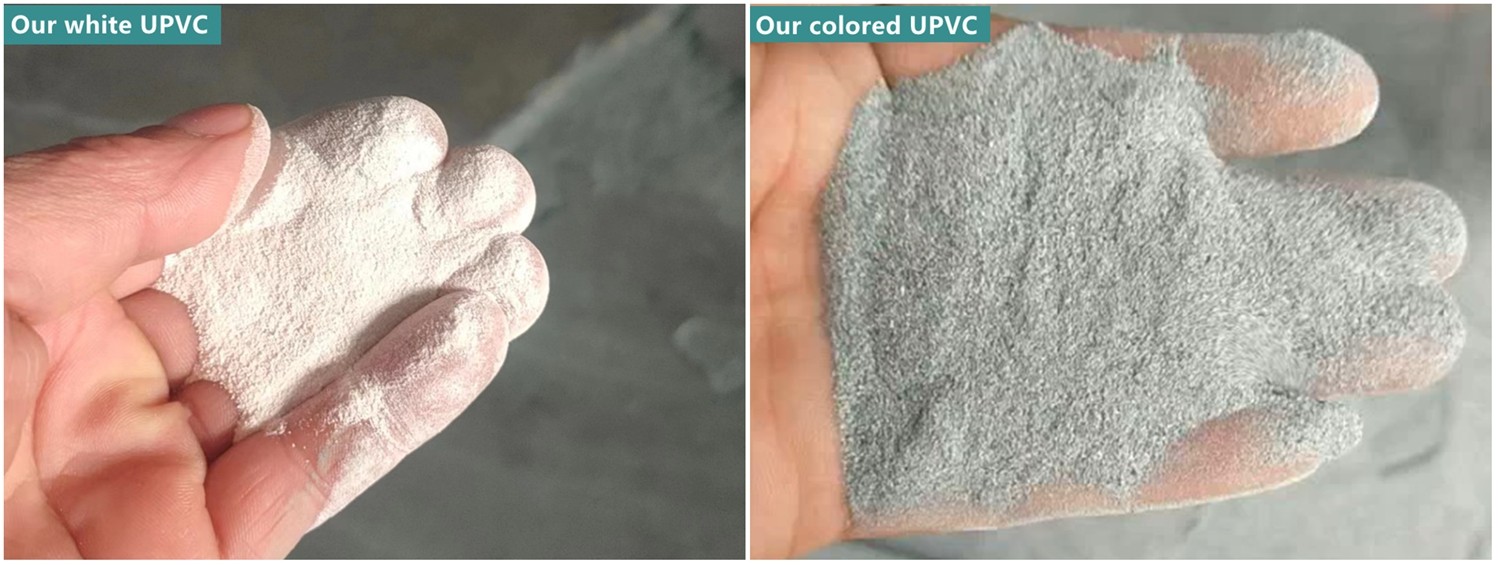

The Unique Raw Material of JINGFANG® PVC plastic formwork: UPVC

UPVC, the full name is Unplasticized Polyvinyl Chloride, is also named Plastic Steel, or PVC-U. It is the upgrading of general PVC that removes plasticizers to achieve better engineering properties, so as to retain the rigid chain structure, and increase the strength.

UPVC strictly adheres to the "Three-No-addition" principle: no plasticizers, no heavy metal stabilizers, no calcium carbonate fillers. It is environmental friendly, corrosion resistant, formaldehyde-free, and has excellent UV resistance performance and outdoor ageing resistance.

Since 10+ years ago, UPVC has been proved to be the most qualified and the optimal raw material selection for PVC formwork.

Except UPVC, there are other different plastic formwork materials including general PVC, PP, ABS in the markets.

We would love to remind:

We would love to remind:

This is a well-known point in this industry by almost manufacturers.

When a supplier denies this point or misleads you, it implies that he doesn't want to use or has never used qualified UPVC to manufacture PVC plastic formworks. It's like a stainless steel products manufacturer doesn't know stainless steel.

Comparison between UPVC and general PVC:

Advantages of UPVC:

1. Higher strength than general PVC.

2. Better UV resistance and temperature resistance than general PVC.

3. Environmental, no plasticizers, no heavy metal stabilizers, formaldehyde-free.

4. Higher resin purity than general PVC.

5. Over 4 times better outdoor anti-aging performance than general PVC.

Disadvantages of UPVC:

Higher cost than general PVC and recycled materials.

Product superiority of PVC plastic formwork:

◆ Reuse ≥ 50 times in plain wooden structures, more in metal frames which offer good protection to edges.

◆ Anti-flaming, avoid the potential safety hazards.

◆ Excellent bending strength.

◆ High impact strength.

◆ Waterproof and moistureproof.

◆ Foaming technology, never delaminates.

◆ Good nails-holding power

◆ Alkali/Chemical resistant

◆ Ageing resistant, temperature resistant and weatherproof.

◆ Uniform smooth concrete surface.

◆ No need releasing oil, easily releasing and cleaning.

◆ Freely cutting/shaping/bending/punching.

◆ Same sizes & applications as plywood formwork.

◆ Matching well with different structures.

◆ Environmental friendly, non-plasticizer, formaldehyde-free.

◆ Recyclable with extra returns.

How To Assemble PVC Plastic Formwork?

Tip 01: Edge distance of nailing/screwing

To prolong the life-span of product, we suggest to leave at least 3-5cm distance from the edge when nailing/screwing on it.

Tip 02: Props distance

In general, we suggest the same props distance as the plywood formworks which you are using. But, it differs a bit according to the frame structures and concrete thickness. The stronger structures, the shorter props distance.

Tip 03: Nailing/screwing distance

Same as the general requirements for all formwork materials, to ensure the average load-bearing capacity of the entire sheet, in addition to the appropriate props distance, we also recommend maintaining an average spacing of nails/screws, such as 30 cm. Especially the corners should be fixed well with nails/screws. Or you can keep the regular way that applied to your structures.

Tip 04: Joint treatment

If you want to avoid the concrete sticking into the joint, you can paint the joint. The regular painting is workable enough. Some of our clients use the gel coat.

Tip 05: Repair the holes of nails or bolts

For the nails holes: normally such holes don’t leak concrete, so not necessary to fix it. If you have strict requirements, you can use glue or wax to cover them.

For the bolt holes: plastic plug or adhesive tape. Another solution: normally the bolt holes of one single project have same diameters and locations. So some clients cut formworks sheets into small round pieces with 1mm smaller diameter, and then insert them into the bolt holes.

Applications Cases of PVC Plastic Formwork:

■ PVC Plastic Formwork for wall:

You can freely cutting , nailing, shaping PVC plastic formwork, no special requirements.

■ PVC Plastic Formwork for slab/floor:

You can keep the same prop distance to PVC plastic formwork as that to plywood formworks, not necessary to change.

■ PVC Plastic Formwork for column:

PVC plastic formwork has good strength and flexibility, you can apply it to square or round column.

■ PVC Plastic Formwork for tunnel:

With premium strength, PVC plastic formwork has multiple applications including the tunnels.

■ PVC Plastic Formwork for high-speed way:

Same as plywood formwork, PVC plastic formwork can also be applied to high-speed ways.

■ PVC Plastic Formwork for bridge:

For bridge, PVC plastic formwork can also be competent well, no worries.

■ Other Special Applications of PVC Plastic Formwork:

JINGFANG® PVC plastic formwork can be laminated with veneers, and then applied to decorations and furniture. There are hundreds of patterns to choose as you like.

Demolding of PVC plastic formwork:

JINGFANG® PVC plastic formwork can keep glossy surface from the beginning to end, so there is no need to spread the releasing oil. Just use mop+water can easily clean it.

Why Choose JINGFANG® PVC plastic formwork?

Shandong Jingfang Import and Export Co., Ltd. is the only factory who persistly adopt "Virgin & Pure UPVC" as the solo main raw material to manufacture PVC plastic formwork all along.

The UPVC accounts for more than 95% (the rest 4~5% is for necessary additives), and we never add any recycled PVC/PP/ABS materials, can guarantee qualified strength, elasticity modulus and UV-resistance, thoroughly solve the deformation/cracking/bending problems of unqualified products.

· Virgin & Pure UPVC as the solo main raw material

· 10+ years manufacturing and export experience

· Strict QC every 1-2 hours during manufacturing

· One of the earliest manufacturers, the only single-minded manufacturer

With advanced automatic production lines, professional production team and independent international trading team, we promise you the best product & import service and are 100% confident being one of the most professional Chinese factory manufacturing PVC plastic formwork.

Please feel free to contact with us whenever you have interest to check more. Our trading team will reply you ASAP within 24 hours.