PVC plastic board formwork, new type plastic concrete shuttering, China supplier

| Trademark/Brand: | JINGFANG® PVC plastic board formwork, new type plastic concrete shuttering, China supplier |

| Raw material: | UPVC (also named Plastic-Steel PVC) |

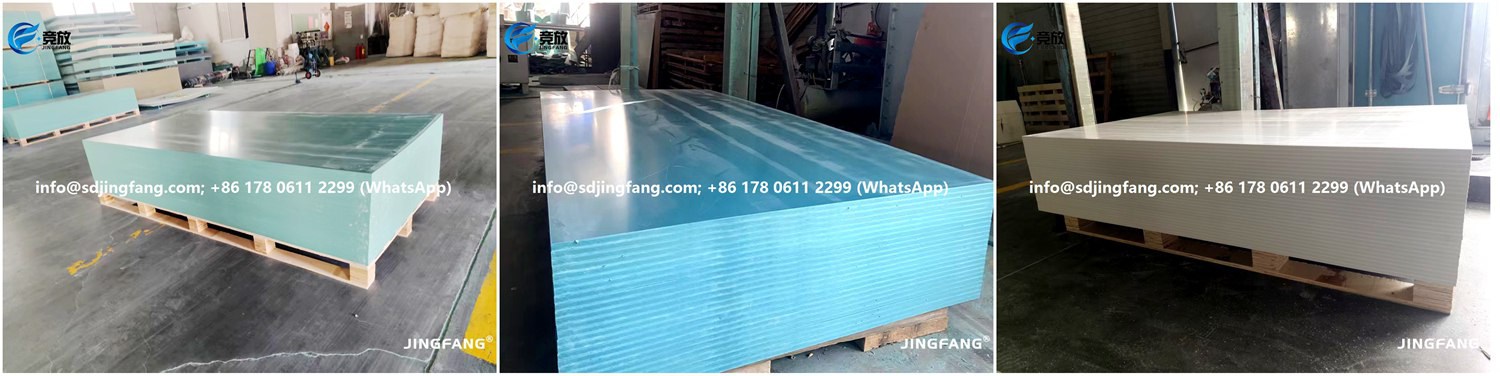

| Width: | up to 1300 mm available |

| Length: | no limits, can be customized |

| Thickness: | 6 – 21 mm available |

| Density: | 700kg/m³±1% (standard), and the 600~900kg/m³ can be customized. |

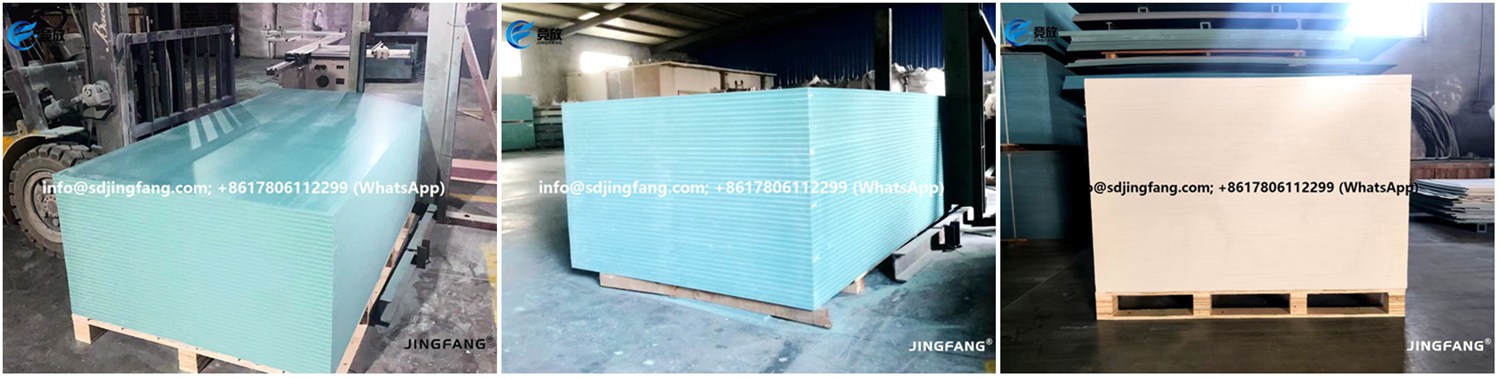

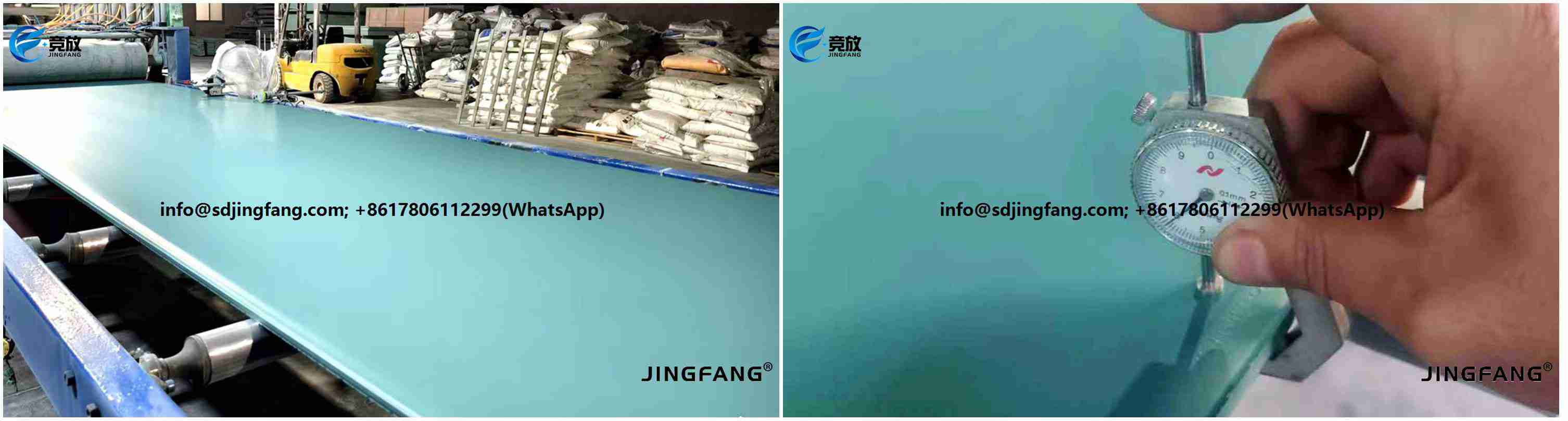

| Color: | Turquoise Green / Azure Blue, others customizable |

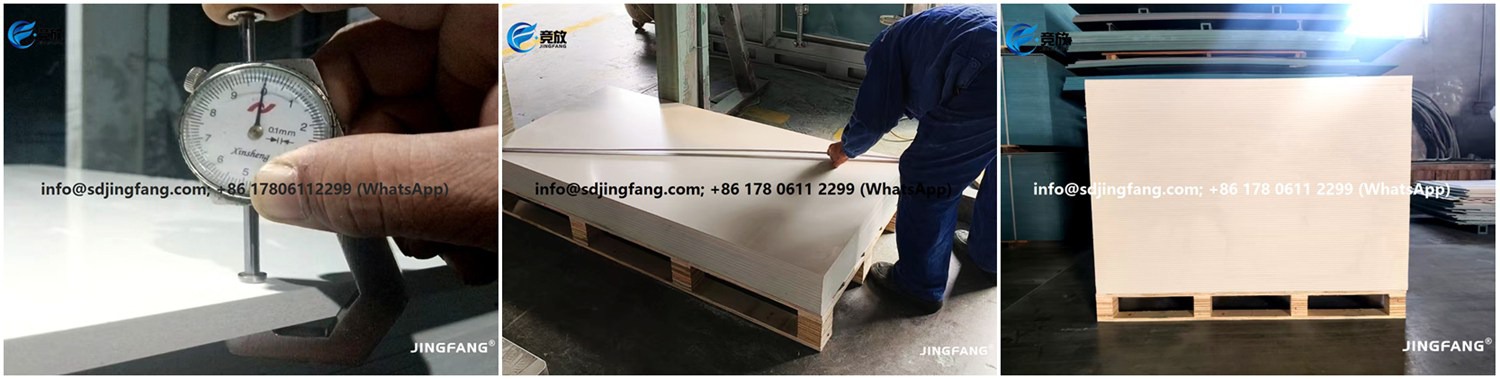

| Loading & Packing: | in bulk or with pallets |

| FOB Port: | Qingdao, Lianyungang, Tianjin, Shanghai, etc. |

| Export Transportation: | FCL/LCL by sea, road or railway |

Brief introduction of JINGFANG® PVC plastic board formwork:

PVC plastic board formwork is new formwork product, which is made of Virgin & Pure UPVC only. It was created by 10+ years ago, under the background of civil engineering worldwide trend "replacing wood with plastic", is a good choice to substitute the traditional formwork materials including plywood /wood /aluminum /steel /bamboo formworks, so as to greatly save the forest sources.

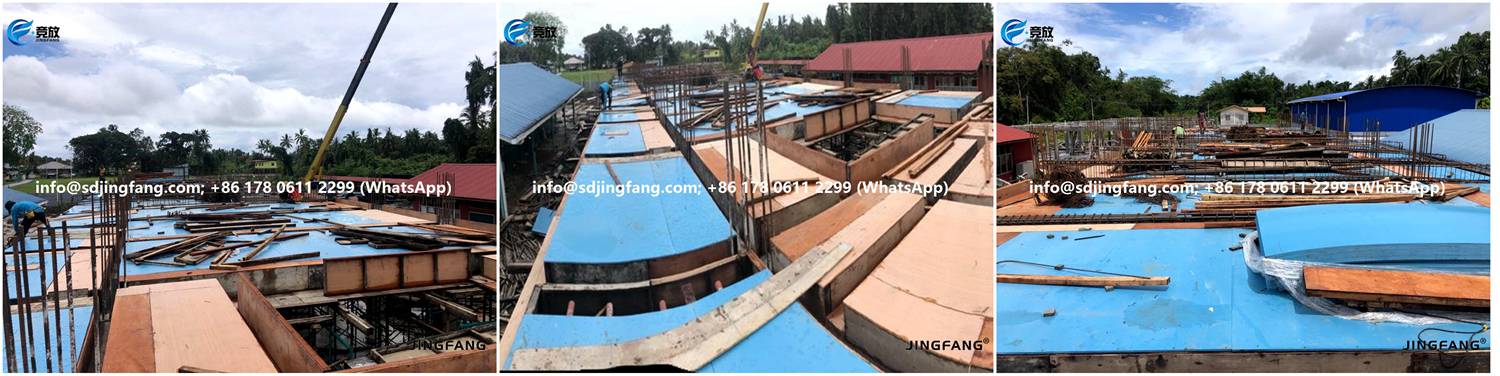

Same as regular formwork products, PVC plastic board formwork can be applied multiply, including wall formwork, slab/floor formwork, column formwork, stairs, tunnel formwork, bridge formwork, etc.

Compared with traditional wood/plywood formworks, the biggest advantage is that PVC plastic board formwork can be reused for 50+ times in plain wooden structures, and much more times in metal frames which can offer good protection to formwork edges.

Compared with steel/aluminum formworks, the advantage is that PVC plastic board formwork is lightweight, and is flexible to cut into any dimensions.

Besides, PVC plastic formwork is waterproof, anti-flaming, 100% recyclable, and no need releasing oil, etc. Recently several years, it's being well-known by tens of countries.

Specifications of PVC plastic board formwork:

| Trademark/Brand: | JINGFANG® PVC plastic board formwork |

| Raw material: | UPVC, also named Plastic-steel PVC |

| Width: | Up to 1300mm available |

| Length: | No limits, can be customized |

| Thickness: | 6~21mm available |

| Density: | 700kg/m³±1% (standard), and the 600~900kg/m³ can be customized |

| Color: | Turquoise Green/Azure blue, others can be customized |

| Loading & packing: | In bulk, or with pallets |

| FOB port: | Qingdao, Lianyungang, Tianjin, Shanghai, etc. |

| Export transportation method: | FCL/LCL by sea, road or railway |

Characteristics and applications of PVC plastic board formwork:

1. Reuse 50+ times, saving much project costs

JINGFANG® PVC plastic board formwork can be reused ≥50 times in plain wooden structures, and much more times in metal frames. This means the lifespan of 1 piece of JINGFANG® PVC plastic board formwork equals to ≥ 5~10 pieces of plywood formwork.

2. Same dimensions & applications as plywood formworks

JINGFANG® PVC plastic board formwork has the same dimensions and applications as conventional plywood formwork, including for wall, slab, column, stairs, tunnel, bridge, etc.

Its usage in preparing, handling, installation and assembly are same as plywood formwork. No changes to the formwork structure and construction process.

3. No need special tools and trainings

JINGFANG® PVC plastic board formwork has excellent screw holding strength, can be freely saw, cut, drill, nail, and shaped into any sizes as desired.

Workers may prepare the JINGFANG® PVC plastic board formwork as the same way that they use conventional plywood formwork.

No additional trainings or special tools required for workers to handle the product.

4. Uniform foaming technology, never delaminates

JINGFANG® PVC plastic board formwork adopts the foaming technology, not layerinng or laminating. It will never delaminate even after reusing 50+ times. So it can be reused continually unless it is badly cracked by violent construction.

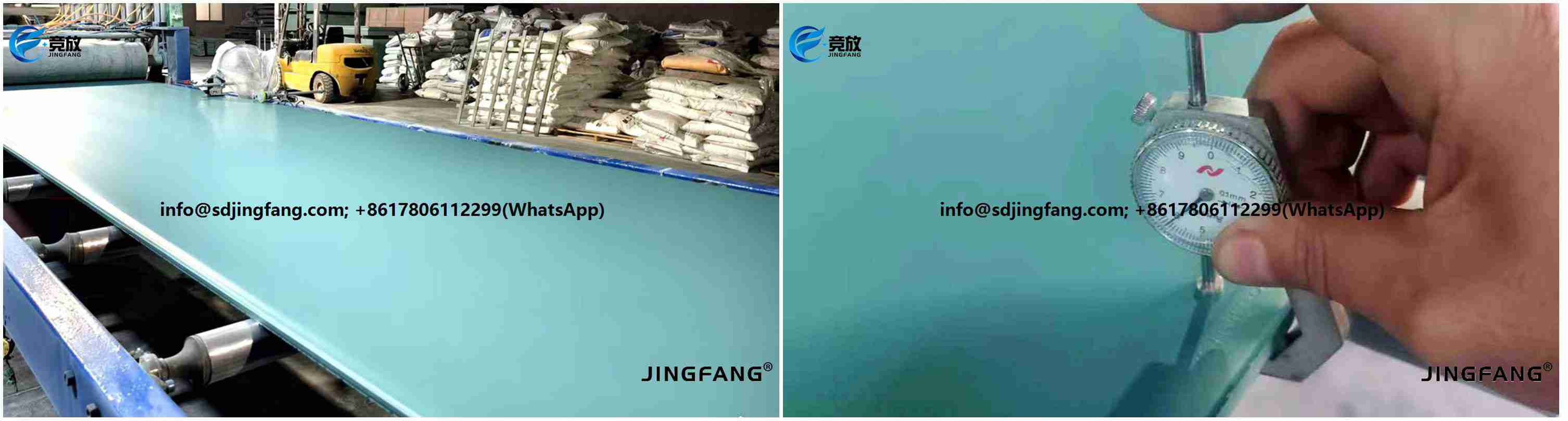

5. Smooth concrete surface, guarantee project quality

Our mirror surface technology ensures JINGFANG® PVC plastic board formwork smooth surface, and is able to maintain its smoothness even after reusing for 50+ times. This helps ensuring all the wall surface in uniform smoothness across first to top floor.

6. High Load-bearing Capacity

JINGFANG® PVC plastic board formwork has good surface hardness with excellent strength in during high impact. This is another important reason why it can be reused 50+ times in a plain wood support structure.

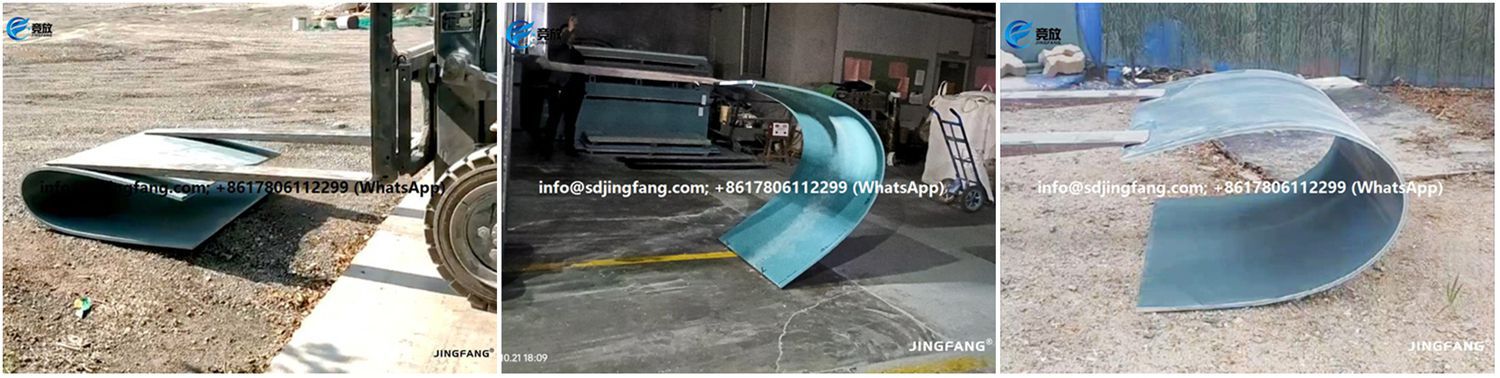

7. High Bending Strength and Elasticity

JINGFANG® PVC plastic board formwork has excellent bending strength. You can curve it freely in your round formwork structure.

Even in winter, JINGFANG® PVC plastic board formworkmaintains its elasticity in bending. Non-fragile.

8. Anti-flaming, avoiding hidden safety hazards

With pure UPVC as the only main material which accounts for over 95%, JINGFANG® PVC plastic board formwork is anti-flaming without hidden safety hazards.

This effectively reduces the fire risk and limits the spread of fire.

9. Weatherproof and 100% Waterproof

JINGFANG® PVC plastic board formwork is 100% waterproof. So it is durable enough to be used, stored or placed at outdoor environment without the need of any extra protection, including under the weather of raining, snowy, in Summer or Winter.

10. UV resistant, Chemical Resistant Against Harsh Environment

UPVC is the upgrading of general PVC. It has over 4 times better outdoor anti-aging performance than general PVC, with lifespan for tens of years. It accounts for over 95% in our product formula, so can guarantee JINGFANG® PVC plastic board formwork the qualified resistance against UV, temperatures and weather.

11. High Temperature Resistant and Freezing-thawing Resistant

JINGFANG® PVC plastic board formwork has good resistance against temperature. No shrinkage, bulge, or deformation under -25℃ to +70℃ . It can be exposed to any weather, raining or snowy, summer or winter. No need to worry about it being weaken by the sunshine or temperature.

12. No Need Releasing Oil, Easily Releasing and Cleaning

With sustaining smooth surface and excellent hardness, JINGFANG® PVC plastic board formwork doesn't stick concrete stubbornly, which ensures it to be easily cleaned with water+mop.

No releasing agent or oil is required before and during concrete demoulding process. Easily cleaning.

Easily demoulded by hands, leaving the wall surface smooth and glossy without the need of secondary plastering.

13. 100% Recyclable with Extra Returns

UPVC is one of the most popular plastic materials in the world. It is easy to resell the used JINGFANG® PVC plastic board formwork to related plastic industries, with higher returns than used plywood formwork. Such as PVC tubes, plastic furniture, cabinet, box, etc.

For full sizes, you can reuse them continually or rent out to other projects;

For small parts, you can can re-sell them to related industries.

14. Environmental friendly, non-plasticizer, formaldehyde-free

JINGFANG® PVC plastic board formwork is made of UPVC material only, never add any wood powder. It adopts foaming technology, not layer or laminated, no any glue is used in manufacturing.

So it is environment friendly, doesn't discharge any infectant or toxic gas. It is in accordance with environmental trend of the earth.

How to assemble PVC plastic board formwork?

Tip 01: Edge distance of nailing/screwing

To prolong the life-span of product, we suggest to leave at least 3-5cm distance from the edge when nailing/screwing on it.

Tip 02: Props distance

In general, we suggest the same props distance as the plywood formworks which you are using. But, it differs a bit according to the frame structures and concrete thickness. The stronger structures, the shorter props distance.

Tip 03: Nailing/screwing distance

Same as the general requirements for all formwork materials, to ensure the average load-bearing capacity of the entire sheet, in addition to the appropriate props distance, we also recommend maintaining an average spacing of nails/screws, such as 30 cm. Especially the corners should be fixed well with nails/screws. Or you can keep the regular way that applied to your structures.

Tip 04: Joint treatment

If you want to avoid the concrete sticking into the joint, you can paint the joint. The regular painting is workable enough. Some of our clients use the gel coat.

Tip 05: Repair the holes of nails or bolts

For the nails holes: normally such holes don’t leak concrete, so not necessary to fix it. If you have strict requirements, you can use glue or wax to cover them.

For the bolt holes: plastic plug or adhesive tape. Another solution: normally the bolt holes of one single project have same diameters and locations. So some clients cut formworks sheets into small round pieces with 1mm smaller diameter, and then insert them into the bolt holes.

Why Choose JINGFANG® PVC plastic board formwork?

Unique advantages No. 1: Using UPVC as the solo main raw material.

From the first year when our factory established until today, JINGFANG® PVC plastic board formwork throughout perseveringly uses the "new & pure UPVC" as the solo main raw material of our product. This brings us high manufacturing cost, but also premium quality and sustaining good markets feedback.

There are 2 types of UPVC raw materials: white color and colored.

Unique advantages No. 2: Qualified UV resistance.

JINGFANG® PVC plastic board formwork guarantees as following:

1) If putting it directly under sunshine, we guarantee no S shape or big U shape deformation .

2) If nailing it onto strips or supports, we guarantee no any warping.

Only qualified raw material and formula can offer you this guarantee.

Unique advantages No. 3: Qualified elasticity modulus.

The elasticity modulus is one of the most important parameters of concrete formwork, which influences quantity of props and project quality. Benefits from the good purity and qualified rigidity of our raw material, JINGFANG® PVC plastic board formwork guarantees qualified elasticity modulus.

Unique advantages No. 4: No any recycled PVC/PP/ABS materials.

JINGFANG® PVC plastic board formwork guarantees: the main raw material "New & Pure UPVC" accounts over 95% among the components (the rest 4~5% is for necessary additives). This is one of the key reasons why we can strictly control the density tolerance to be within ±0.5%.

Unique advantages No. 5: Strict & accurate quality control.

Every 1-2 hours, we strictly check the density and weight to avoid raw material problems and guarantee the stable density. And we clearly mark the accurate density and thickness error in quotation sheet. We are not that kinds of suppliers who blur these two important specifications. Our QC is as following:

1) Dimension tolerance: Thickness ≤0.1mm; Diagonal ≤3mm

2) Density tolerance: g/cm³±0.5%

Unique advantages No. 6: Uniform foaming.

The uniform foaming is another important guarantee for product quality, which guarantees stable and average strength of the full sheet. To get uniform foaming, strictly controlled manufacturing speed and qualified raw materials are both necessary. Some other manufacturers fasten the speed to lower cost.

Unique advantages No. 7: Qualified nails-holding power.

Even you nail it by the edge with less than 2cm distance, JINGFANG® PVC plastic board formwork can still hold the nails well without cracking. This profits from the qualified raw material, which brings excellent toughness and rigidity.

Unique advantages No. 8: Strong export packages.

With years' experience and feedback, we have settled down the strong packing for export:

1. New non-fumigation pallets made of 18mm plywood sheets: we use new materials to make pallets, not recycled. One pallet can hold 4 tons weight.

2. Plywood sheets to protect all the outside.

3. Steel strips to fix the package.

4. Metal corners to avoid the belt scratches.

5. Vertical packages use 2 pallets to protect the sheets from tilting.

6. Reinforce the last row with fastening ropes, to avoid the pallets moving during transportation.

Please freely contact with us for more details. Our international trading team will repeat you timely within 24 hours.