What is UPVC?

UPVC, the full name is Unplasticized Polyvinyl Chloride, is also named Plastic Steel, or PVC-U. It is the upgrading of general PVC that removes plasticizers to achieve better engineering properties, so as to retains the rigid chain structure, and increase the strength

It strictly adheres to the "Three-No-addition" principle: no plasticizers, no heavy metal stabilizers, no calcium carbonate fillers.

Except UPVC, there are other different plastic formwork materials including general PVC, PP, ABS in the markets.

But since over 10 years ago when PVC formwork was invented, UPVC has been proved to be the most qualified and the optimal raw material selection for PVC formwork. This is a well-known point in this industry by almost manufacturers.

Compared with general PVC, UPVC has many obvious advantages, including: higher strength, better UV resistance and temperature resistance, higher resin purit. Especially it has over 4 times better outdoor anti-aging performance than the general PVC, etc. But, it also has higher cost.

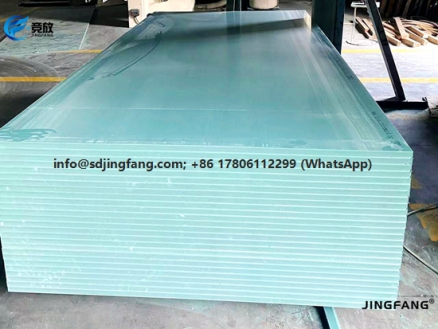

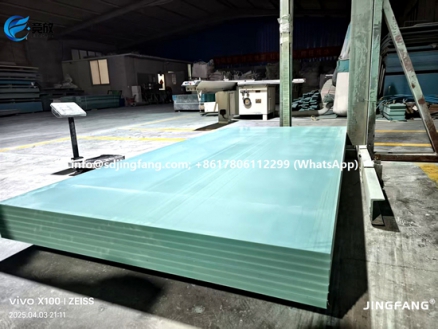

JINGFANG® UPVC plastic formwork adopts“Virgin & Pure UPVC” as the solo main raw material, which accounts for more than 95% (the rest 4~5% is for necessary additives), and we never add any recycled PVC/PP/ABS materials, can guarantee qualified strength, elasticity modulus and UV-resistance, thoroughly solve the deformation/cracking/bending problems of unqualified products.

Unique advantages No. 1: Using UPVC as the solo main raw material

From the first year when our factory established until today, we throughout perseveringly use the “ Virgin & Pure UPVC” as the solo main raw material of our product. This brings us high manufacturing cost, but also premium quality and sustaining good markets feedback. There are 2 types of UPVC raw materials: white color and colored.

Unique advantages No. 2: Qualified UV resistance

JINGFANG® UPVC Plastic Formwork guarantees as following:

1) If putting it directly under sunshine, we guarantee no S shape or big U shape deformation .

2) If nailing it onto strips or supports, we guarantee no any warping.

Only qualified raw material and formula can offer you this guarantee.

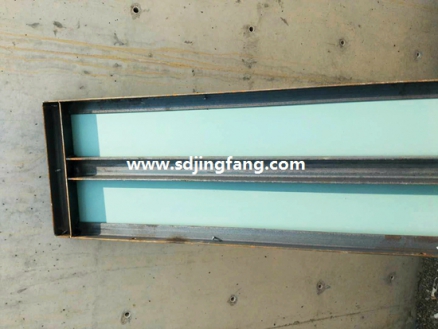

Unique advantages No. 3: Qualified elasticity modulus

The elasticity modulus is one of the most important parameters of concrete formwork, which influences quantity of props and project quality. Benefits from the good purity and qualified rigidity of our raw material, JINGFANG® UPVC Plastic Formwork guarantees qualified elasticity modulus.

Unique advantages No. 4: No any recycled PVC/PP/ABS materials

JINGFANG® UPVC Plastic Formwork guarantees: the main raw material “Virgin & Pure UPVC” accounts over 95% among the components (the rest 4~5% is for necessary additives). This is one of the key reasons why we can strictly control the density tolerance to be within ±0.5%.

Unique advantages No. 5: Strict & accurate quality control

Every 1-2 hours, we strictly check the density and weight to avoid raw material problems and guarantee the stable density. And we clearly mark the accurate density and thickness error in quotation sheet. We are not that kinds of suppliers who blur these two important specifications. Our QC is as following:

1) Dimension tolerance: Thickness ≤0.1mm; Diagonal ≤3mm

2) Density tolerance: g/cm³±0.5%

Unique advantages No. 6: Uniform foaming

The uniform foaming is another important guarantee for product quality, which guarantees stable and average strength of the full sheet. To get uniform foaming, strictly controlled manufacturing speed and qualified raw materials are both necessary. Some other manufacturers fasten the speed to lower cost.

Unique advantages No. 7: Qualified nails-holding power

Even you nail it by the edge with less than 2cm distance, JINGFANG® UPVC Plastic Formwork can still hold the nails well without cracking. This profits from the qualified raw material, which brings excellent toughness and rigidity.

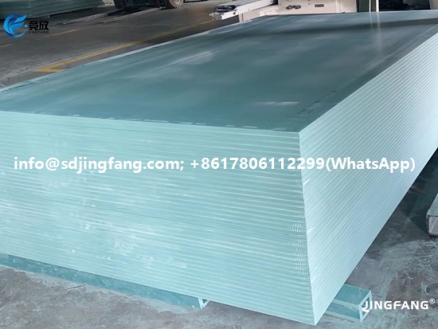

Unique advantages No. 8: Strong export packages

With years’experience and feedback, we have settled down the strong packing for export:

· New non-fumigation pallets made of 18mm plywood sheets: we use new materials to make pallets, not recycled. One pallet can hold 4 tons weight.

· Plywood sheets to protect all the outside.

· Steel strips to fix the package.

· Metal corners to avoid the belt scratches.

· Vertical packages use 2 pallets to protect the sheets from tilting.

· Reinforce the last row with fastening ropes, to avoid the pallets moving during transportation.